In the complex world of inventory management, understanding SKUs (Stock Keeping Units) is paramount. SKUs serve as the fundamental building blocks of efficient warehouse operations, product tracking, and sales analysis. This seemingly simple code holds the key to unlocking a wealth of information, enabling businesses to optimize their inventory levels, streamline fulfillment processes, and ultimately, boost profitability. This article delves into the crucial role of SKUs in achieving effective inventory management, exploring how these unique identifiers empower businesses to gain a competitive edge.

From minimizing stockouts and reducing carrying costs to improving order accuracy and enhancing customer satisfaction, effective SKU management is essential for success in today’s competitive market. Whether you are a small business owner just starting out or a seasoned supply chain professional, mastering the art of SKU creation and utilization can transform your inventory management practices. This article will provide a comprehensive guide to understanding and implementing SKUs effectively, offering practical insights and actionable strategies for leveraging the power of these essential codes.

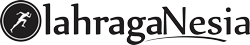

What is a SKU?

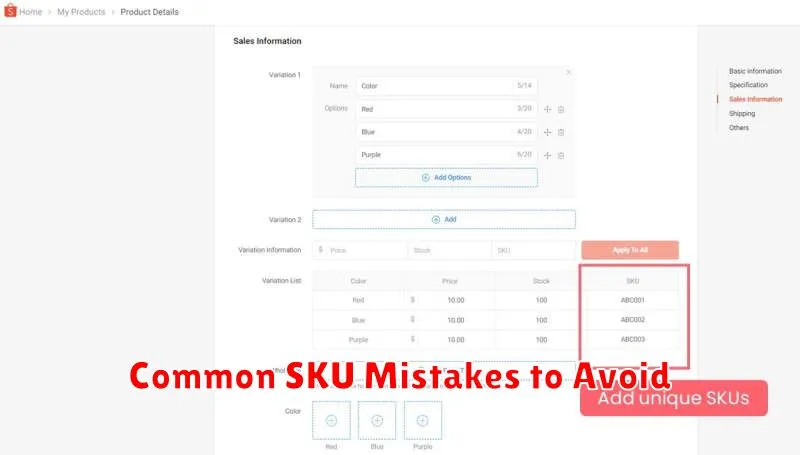

A SKU, or Stock Keeping Unit, is a unique alphanumeric code used to identify and track inventory. It’s essentially a product’s internal ID within a specific business. Think of it as a product’s fingerprint, differentiating it from all other items in stock.

SKUs can vary in length and format, often incorporating relevant information such as manufacturer, product variations (like color or size), and even location within a warehouse. For example, a blue, medium t-shirt might have a different SKU than a red, large t-shirt, even if they are from the same brand and style.

Unlike UPCs (Universal Product Codes) or EANs (European Article Numbers) which are standardized across industries, SKUs are unique to each business. This allows businesses to tailor their SKUs to their specific inventory management needs.

The Importance of SKUs in Inventory Management

SKUs are fundamental to efficient inventory management, providing a granular level of control and visibility. They enable accurate tracking of stock levels, which is crucial for preventing stockouts and overstocking. Real-time insights into inventory quantities empower businesses to make informed decisions about purchasing, production, and sales strategies.

Efficient inventory management translates directly to cost savings. By minimizing waste due to spoilage or obsolescence, and optimizing storage space utilization, businesses can significantly improve their bottom line. Accurate SKUs are also essential for effective cycle counting and inventory audits, streamlining these often complex processes.

Beyond simply tracking quantities, SKUs enable businesses to analyze sales data and identify trends. By understanding which products are performing well and which are lagging, businesses can make data-driven decisions about pricing, marketing, and product development. This data-driven approach is invaluable for maximizing profitability and staying competitive.

Creating Effective SKUs: Best Practices and Examples

Creating effective SKUs involves a strategic approach to ensure they are unique, informative, and supportive of efficient inventory management. Here are some best practices:

Key Considerations:

- Uniqueness: Each SKU must be unique to a specific product variant.

- Clarity: Avoid confusing characters like “O” and “0”.

- Brevity: Keep SKUs concise for easier data entry and scanning.

- Consistency: Follow a consistent format across all products.

- Scalability: Design your SKU system to accommodate future product expansion.

Examples:

Consider a blue, medium-sized t-shirt. A poorly designed SKU might be “TSHIRTBLUE”. A more effective SKU could be “TSH-BLU-M”, incorporating product category (TSH), color (BLU), and size (M). For a red, large version, the SKU would be “TSH-RED-L”.

Adding more detail is possible. If the t-shirt has a specific neckline (e.g., “V”), the SKU could become “TSH-BLU-M-V”.

By following these best practices, businesses can create SKUs that improve warehouse efficiency, inventory tracking, and overall business operations.

How SKUs Streamline Warehouse Operations and Order Fulfillment

SKUs play a crucial role in optimizing warehouse operations and ensuring efficient order fulfillment. By utilizing unique SKUs, warehouses can effectively manage and track inventory levels, leading to improved organization and reduced errors.

Location Precision: SKUs enable precise location identification within the warehouse. Whether using bin locations, shelf numbers, or zone designations, associating SKUs with specific locations allows warehouse staff to quickly locate items, minimizing search time and improving picking efficiency.

Streamlined Picking and Packing: With clear SKU identification, order picking becomes a streamlined process. Warehouse staff can easily identify the correct items for each order, reducing the risk of picking errors and ensuring accurate order fulfillment.

Inventory Control and Accuracy: SKUs facilitate accurate inventory counts and tracking. By scanning SKUs during receiving and shipping processes, warehouses can maintain real-time inventory visibility, minimizing discrepancies and preventing stockouts or overstocking situations.

Efficient Order Processing: SKUs simplify order processing by providing a standardized identifier for each product. This enables automated systems to quickly process orders, generate pick lists, and track shipments, resulting in faster order turnaround times and improved customer satisfaction.

Using SKUs to Track Sales Data and Inventory Trends

SKUs provide the granular data necessary for insightful sales tracking and inventory trend analysis. By associating sales data with specific SKUs, businesses gain a clear understanding of which products are performing well and which are lagging.

This data enables data-driven decision-making regarding pricing strategies, marketing campaigns, and inventory replenishment. Analyzing SKU-level sales data reveals seasonal trends, allowing for proactive inventory adjustments to meet anticipated demand fluctuations.

Furthermore, tracking sales data by SKU helps identify slow-moving or obsolete inventory. This information is crucial for minimizing storage costs and preventing losses associated with expired or outdated products. By pinpointing underperforming items, businesses can implement targeted promotions or clearance strategies to optimize inventory turnover.

Inventory trend analysis based on SKU performance allows for more accurate demand forecasting. Historical sales data for each SKU can be used to predict future demand, ensuring optimal stock levels and minimizing the risk of stockouts or overstocking. This, in turn, improves customer satisfaction and operational efficiency.

Integrating SKUs with Your E-Commerce Platform

Seamless integration between your SKUs and e-commerce platform is crucial for streamlined operations. A well-integrated system automates key processes, saving time and minimizing errors.

Most platforms allow direct SKU entry during product creation. Ensure the SKU field is mandatory to prevent issues later. Connect your SKU data with inventory management tools within the platform to automatically update stock levels as orders are processed.

Consider leveraging import/export functionalities. This allows bulk updates and simplifies synchronizing data with external systems. Regular data synchronization is essential to maintain accurate inventory records and avoid discrepancies.

Finally, explore platform-specific plugins or extensions that offer advanced SKU management features. These can include automated SKU generation, barcode scanning integration, and enhanced reporting capabilities.

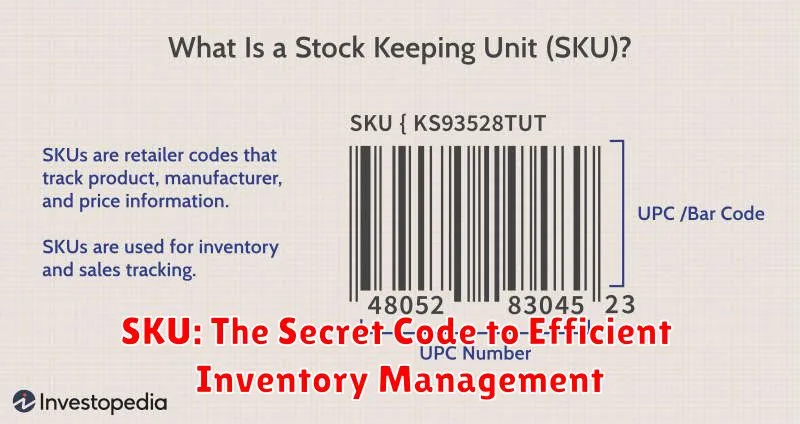

Common SKU Mistakes to Avoid

Creating effective SKUs is crucial for inventory management. Avoiding these common mistakes can save you time and prevent future headaches.

Using Meaningful Characters

Avoid using characters that can be misinterpreted by systems or humans. Do not use spaces, slashes, or special characters like commas or apostrophes. Stick to alphanumeric characters.

Starting with a Zero

While tempting, leading zeros can be problematic with certain software. Ensure your system handles leading zeros correctly or avoid them altogether.

Making SKUs Too Long

Overly long SKUs are cumbersome to use. Keep them concise and focus on essential information. A good rule of thumb is to aim for 8-12 characters.

Using Manufacturer’s SKUs

While seemingly convenient, relying solely on manufacturer SKUs can create confusion, especially if you stock multiple brands. Develop your own unique SKU system.

Advanced SKU Strategies for Complex Products

Managing complex products, such as those with numerous variations or customizable options, requires a more sophisticated SKU structure. A simple sequential numbering system often proves inadequate. Configurable products, like furniture with different fabric and color choices, benefit from incorporating identifiers for each attribute directly within the SKU.

For example, a sofa could have a base SKU of “SOFA-001”. Variations, such as color and fabric, are then appended. “SOFA-001-RED-VELVET” designates a red velvet sofa, while “SOFA-001-BLUE-LINEN” represents a blue linen version. This attribute-based SKU system allows for immediate identification of specific product configurations, simplifying inventory tracking and order fulfillment.

Bundled products also require special consideration. Instead of assigning a new SKU to every unique bundle, consider using a base SKU for the individual products and a separate identifier for the bundle itself. For example, “BUNDLE-001” could represent a package containing “SHIRT-001” and “PANTS-002”. This strategy keeps individual product SKUs consistent while still allowing for tracking of bundled sales.

Finally, serialized inventory, such as electronics with unique serial numbers, demands incorporating this information into the SKU for precise tracking. This can be appended to the end of the main SKU, ensuring each individual item is uniquely identifiable.

Real-World Examples of Effective SKU Implementation

Let’s examine how different businesses leverage SKUs for optimized inventory control. A clothing retailer might use the SKU “TSH-BLU-S-COT” to represent a blue, small, cotton T-shirt. This clearly differentiates it from “TSH-RED-M-SIL” which signifies a red, medium, silk T-shirt. This system allows for quick identification and sorting during warehousing and fulfillment.

An electronics store might adopt a more numerical approach. “LAP-15-I7-512-SLV” could denote a 15-inch laptop with an Intel i7 processor, a 512GB SSD, and a silver finish. A different model, “LAP-17-I5-256-BLK,” would instantly be recognized as a 17-inch laptop with an Intel i5 processor, a 256GB SSD, and a black finish. These specific SKUs streamline stocktaking and prevent confusion between similar products.

A furniture company dealing with variations in materials and finishes might use a system like “CH-OAK-LTH-BRN,” designating a chair made of oak with leather upholstery in brown. This structure allows for precise tracking of each variation, contributing to efficient order management and production planning.