Mastering bulk orders is crucial for scaling your e-commerce business. Efficiently managing large order volumes requires a streamlined fulfillment process. This article will provide you with the essential strategies and best practices to optimize your operations for bulk order fulfillment, minimizing processing time and maximizing profitability. Learn how to handle increased demand, reduce errors, and ultimately improve customer satisfaction when dealing with bulk orders. From inventory management and warehouse organization to shipping and handling, we’ll cover the key elements needed to achieve seamless e-commerce fulfillment.

Processing bulk orders efficiently presents unique challenges for e-commerce businesses. This article will explore the complexities of high-volume order processing and offer practical solutions for navigating these hurdles. Discover how to effectively utilize technology, optimize your workflow, and develop robust systems to meet the demands of bulk order fulfillment. Whether you’re a growing business preparing for expansion or an established enterprise seeking to enhance efficiency, this guide offers valuable insights to master bulk orders and streamline your e-commerce fulfillment process.

Understanding the Challenges of Bulk Orders

Bulk orders, while offering significant revenue potential, present unique challenges to e-commerce businesses. Successfully navigating these challenges is crucial for maintaining profitability and customer satisfaction. One primary concern is inventory management. Having sufficient stock on hand to fulfill a large order without jeopardizing availability for regular customers requires careful planning and forecasting.

Logistical complexities also increase with bulk orders. Shipping large quantities efficiently and cost-effectively requires different strategies compared to individual orders. Packaging, labeling, and handling become more intricate, demanding streamlined processes. Furthermore, quality control becomes paramount. Ensuring each item in a bulk order meets the required standards requires rigorous checking procedures to avoid returns and damage to your brand’s reputation.

Finally, customer communication is vital. Keeping bulk order customers informed about order status, shipping timelines, and any potential delays helps manage expectations and maintain a positive relationship.

Optimizing Your Inventory Management for Bulk Orders

Effective inventory management is crucial for successfully handling bulk orders. Forecasting demand accurately is the first step. Analyzing historical sales data, current market trends, and any pre-orders can provide valuable insights for predicting bulk order volumes.

Inventory allocation is also essential. Reserve sufficient stock specifically for anticipated bulk orders to avoid disrupting regular order fulfillment. Consider implementing a dedicated inventory holding area for these larger orders to streamline picking and packing processes.

Real-time inventory tracking is vital. Utilize a robust inventory management system that provides up-to-the-minute data on stock levels. This allows for proactive reordering and prevents stockouts, especially when dealing with large-volume orders.

Finally, regular inventory audits are necessary to ensure accuracy and identify any discrepancies between physical stock and recorded inventory. This helps maintain accurate inventory data for informed decision-making related to bulk order fulfillment.

Efficient Order Processing and Fulfillment

Efficient processing and fulfillment are crucial for handling bulk orders. Automation plays a key role in streamlining these processes. Consider integrating your e-commerce platform with your inventory management and shipping systems.

Automated order processing reduces manual data entry, minimizing errors and accelerating order fulfillment. This includes automated order confirmation, invoice generation, and shipping label creation.

Optimized picking and packing processes are essential. Organize your warehouse efficiently to facilitate quick and accurate retrieval of bulk items. Consider using barcode scanners or RFID technology to track inventory and ensure accuracy during picking.

Choosing the right shipping carrier is vital for bulk orders. Negotiate discounted rates with carriers capable of handling large shipments. Employ strategies like consolidated shipping to combine multiple orders into single shipments, thereby reducing shipping costs.

Effective Communication with Bulk Order Customers

Clear and proactive communication is crucial for managing bulk orders effectively. This ensures customer satisfaction and minimizes potential misunderstandings.

Establish dedicated communication channels for bulk order customers. This could be a dedicated email address, phone number, or even a designated account manager. This personalized approach strengthens the customer relationship and facilitates efficient communication.

Provide regular updates on order status, including processing, shipping, and delivery. Anticipate potential delays and communicate them promptly. Transparency builds trust and reduces customer anxiety.

Offer multiple communication methods to cater to individual preferences. Some customers might prefer email updates, while others might prefer phone calls. Flexibility demonstrates a customer-centric approach.

Document all communication meticulously. This creates a valuable record for reference in case of disputes or discrepancies.

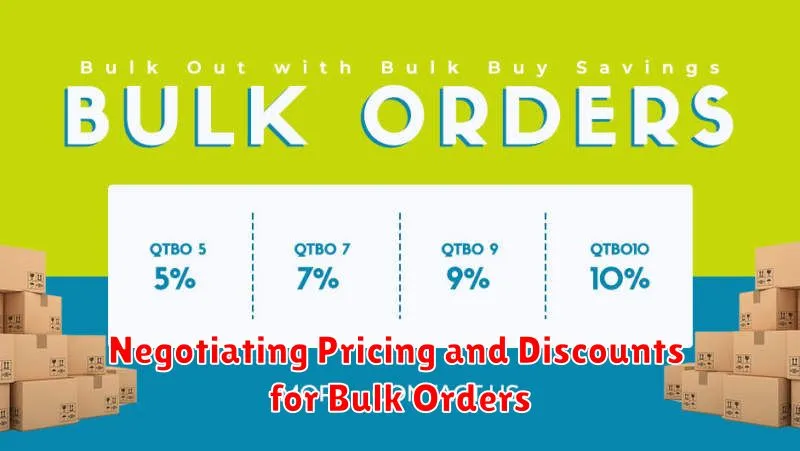

Negotiating Pricing and Discounts for Bulk Orders

Negotiating bulk order pricing requires a strategic approach. Clearly understand your costs, including production, packaging, and shipping, to establish your lowest acceptable price. This allows you to confidently offer discounts while maintaining profitability.

Tiered pricing is a common strategy, offering larger discounts for higher volume orders. This incentivizes customers to purchase more and can increase overall sales. For example:

- 100-250 units: 5% discount

- 251-500 units: 10% discount

- 501+ units: 15% discount

Consider other incentives beyond direct discounts. Offering expedited shipping, customized packaging, or exclusive add-ons can add value for bulk buyers without drastically impacting profit margins.

Finally, document all agreements clearly. This prevents misunderstandings and ensures a smooth transaction for both parties. Specify payment terms, delivery schedules, and any other relevant details in a written contract or order confirmation.

Managing Shipping and Logistics for Large Orders

Efficient shipping and logistics are crucial for handling bulk orders. Negotiating discounted rates with shipping carriers is essential due to the higher volume. This can significantly reduce costs and improve profit margins.

Packaging optimization is another key factor. Utilizing appropriate packaging materials minimizes shipping costs and protects goods from damage during transit. Consider offering tiered shipping options, like expedited or standard delivery, to cater to diverse customer needs and budget preferences.

Warehouse organization plays a vital role in bulk order fulfillment. Implementing a robust inventory management system allows for quick and accurate order processing. Prioritizing bulk orders and allocating dedicated packing stations ensures timely dispatch and minimizes delays.

Leveraging Technology for Bulk Order Management

Technology plays a crucial role in efficiently managing bulk orders. Inventory management systems track stock levels in real-time, preventing overselling and ensuring accurate fulfillment. These systems can also automate purchase orders when stock falls below a predetermined threshold.

Order management systems (OMS) centralize order data from various sales channels, simplifying the process of tracking and managing large volumes of orders. An OMS can automate workflows, such as order routing and fulfillment, reducing manual intervention and potential errors.

Warehouse management systems (WMS) optimize warehouse operations for bulk order fulfillment. They can guide picking and packing processes, manage shipping labels, and track inventory movement within the warehouse. Integration between WMS and other systems, like OMS and inventory management systems, is essential for seamless bulk order processing.

Finally, consider shipping management software to automate carrier selection, generate shipping labels, and track shipments in bulk. This software often integrates with various carriers, allowing businesses to compare rates and choose the most cost-effective shipping options for large orders.