Running a successful business requires diligent inventory management. One of the most significant challenges businesses face is handling out-of-stock products. Out-of-stock situations can lead to lost sales, frustrated customers, and damage to your brand’s reputation. This article will explore effective strategies for mastering inventory and minimizing the negative impact of out-of-stock products. We will delve into proactive planning, demand forecasting, and efficient supplier relationships to ensure smooth operations and satisfied customers. Learn how to take control of your inventory and optimize your business for maximum profitability.

Mastering inventory is crucial for maintaining a competitive edge in today’s demanding market. Effectively managing out-of-stock products requires a comprehensive understanding of your inventory flow, customer demand patterns, and supply chain dynamics. From implementing robust inventory control systems to developing backorder strategies and optimizing warehouse organization, this article provides practical guidance and actionable steps for handling out-of-stock products efficiently. By the end of this article, you will be equipped with the knowledge and tools to navigate inventory challenges, minimize disruptions, and ensure customer satisfaction.

The Impact of Out-of-Stock Products on Your Business

Out-of-stock (OOS) situations can significantly impact a business’s bottom line and customer satisfaction. Lost sales are an immediate consequence, as customers are unable to purchase desired products. This can lead to lost revenue and a decrease in profit margins.

Beyond immediate financial losses, stockouts can damage a company’s brand reputation. Customers faced with repeated OOS situations may perceive the business as unreliable and seek alternatives from competitors. This can result in decreased customer loyalty and a negative impact on long-term growth.

Furthermore, stockouts can disrupt internal operations. Increased customer service inquiries related to product availability can strain resources. Expediting orders to fulfill backorders can also lead to increased operational costs.

Proactive Measures to Prevent Stockouts

Preventing stockouts requires a proactive approach to inventory management. Implementing the following strategies can significantly reduce the likelihood of encountering this issue.

Demand Forecasting

Accurately predicting future demand is crucial. Utilize historical sales data, consider seasonal trends, and incorporate marketing campaign information to create realistic demand forecasts. Sophisticated forecasting software can assist in this process.

Safety Stock

Maintain a safety stock buffer to account for unexpected demand spikes or delays in supply chain replenishment. Calculate the appropriate safety stock level based on historical data and risk tolerance.

Supplier Relationship Management

Establish strong relationships with reliable suppliers. Open communication and collaborative planning can help ensure timely deliveries and prevent supply chain disruptions.

Inventory Tracking

Implement a robust inventory tracking system. Real-time visibility into stock levels allows for prompt reordering and prevents stockouts before they occur. Consider automated inventory systems for increased accuracy and efficiency.

Strategies for Managing Out-of-Stock Products

When a product becomes out-of-stock, swift and decisive action is crucial to mitigate negative consequences. Implement these strategies to effectively manage the situation:

Prioritize Backorders

If the product is expected to be restocked soon, offer backorders. This allows customers to reserve their purchase and ensures they receive the product as soon as it’s available. Clearly communicate expected shipping dates to manage expectations.

Partial Fulfillment

If possible, offer to partially fulfill the order with available items and ship the remaining items when they are back in stock. This shows a commitment to fulfilling the customer’s needs, even if not immediately.

Suggest Substitutions

Offer similar products as substitutes. Highlight the comparable features and benefits of the alternative product. Offering a discount on the substitute can further incentivize the purchase.

Communicating with Customers About Out-of-Stock Items

Transparency is key when dealing with out-of-stock situations. Inform customers promptly and clearly about the unavailability of a product. Avoid vague language; instead, provide specific details about the reason for the stockout and the expected restocking date, if known.

Offer alternative solutions. Suggest similar products that are currently in stock or offer to notify the customer when the desired item becomes available again. This proactive approach demonstrates customer-centric service and can help mitigate potential frustration.

Maintain consistent communication. If the restocking date changes, update the customer immediately. This consistent communication builds trust and manages expectations effectively.

Apologize for the inconvenience. A sincere apology acknowledges the customer’s frustration and shows that you value their business.

Consider offering a small incentive, such as a discount on their next purchase, to compensate for the inconvenience. This gesture can help retain customer loyalty despite the stockout.

Alternative Solutions for Out-of-Stock Products

When a product is out of stock, offering alternative solutions can maintain customer satisfaction and potentially drive sales of other items. Substitution is a key strategy. Suggesting a similar product, perhaps with upgraded features or at a comparable price point, can fulfill the customer’s need.

Bundling related products is another effective approach. If a specific item is unavailable, create a bundle with a substitute and complementary items at a special price. This adds value for the customer and increases the average order value.

Pre-orders are a viable option for anticipated stock replenishments. This allows customers to secure the desired item and provides valuable data for forecasting future demand.

Finally, consider drop-shipping. Partnering with another supplier to fulfill orders directly can mitigate stockouts, especially for less frequently ordered items or during peak demand periods.

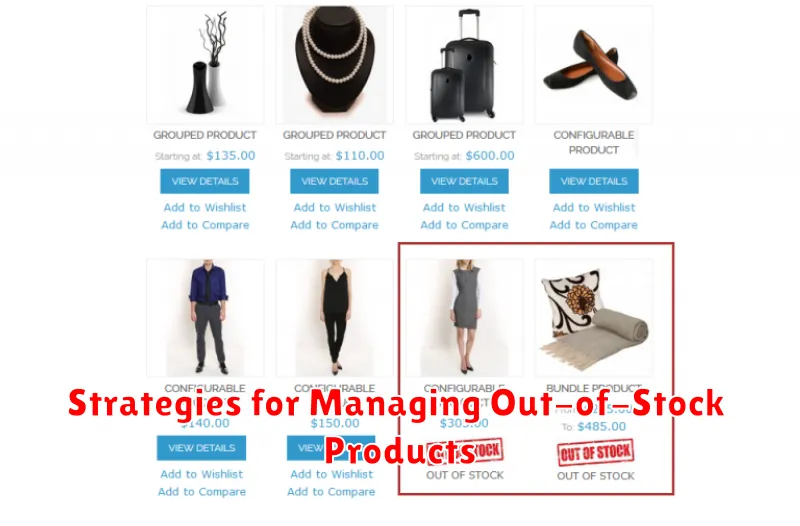

Utilizing Back-in-Stock Notifications

Back-in-stock notifications are a powerful tool for managing customer expectations and recapturing lost sales when products are temporarily unavailable. They allow customers to sign up for an email or other notification that alerts them when a specific out-of-stock item becomes available again.

Implementing a back-in-stock notification system provides several key benefits:

- Reduced lost sales: By capturing customer interest while a product is out of stock, businesses can convert potential lost sales into future purchases.

- Improved customer experience: Providing a proactive way for customers to be notified of product availability enhances their overall experience and fosters loyalty.

- Valuable data insights: Tracking sign-ups for back-in-stock notifications can provide valuable data on product demand, helping businesses make informed inventory management decisions.

Effective implementation of back-in-stock notifications requires careful consideration of several factors:

- Clear and concise notification messaging: Ensure notifications are easy to understand and provide essential information about the product’s availability.

- Easy sign-up process: A simple and streamlined sign-up process encourages more customers to opt-in for notifications.

- Timely and accurate alerts: Notifications should be sent promptly once the product is back in stock, ensuring customers have a chance to make a purchase before it potentially sells out again.

Analyzing Out-of-Stock Data to Optimize Inventory Management

Analyzing out-of-stock data is crucial for optimizing inventory management and minimizing future stockouts. This involves identifying trends and patterns related to which products are frequently out of stock, when they go out of stock, and for how long. Data analysis helps pinpoint the root causes of stockouts, enabling informed decision-making.

Key metrics to track include:

- Frequency of stockouts: How often a specific product is out of stock.

- Duration of stockouts: The length of time a product remains unavailable.

- Lost sales due to stockouts: The potential revenue lost because a product wasn’t available.

By examining these metrics, businesses can identify products with recurring stockout issues. This data-driven approach allows for adjusting reorder points, optimizing safety stock levels, and improving forecasting accuracy.